Inconel 718 for Metal 3D Printing

+

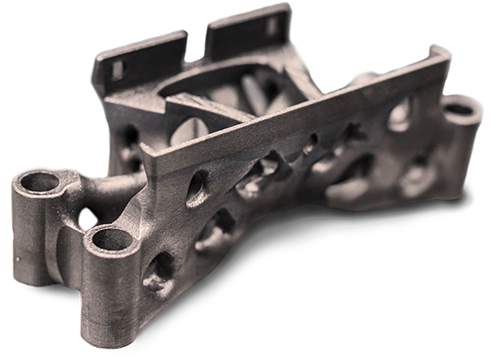

3D printed Inconel 718 enables lighter and more cost-effective solutions. The advantages and possibilities of printing are emphasized with the Inconel 718 material, thats mechanical properties, corrosion and heat resistance clearly exceed those of more traditionally used materials.

Inconel 718

Inconel 718 (IN718) is a high-strength, corrosion-resistant metal and can be used at temperatures from around -200 °C to 700 °C. The characteristic to retain strength over this wide temperature range makes IN718 an attractive choice for extreme environments, whether in high-temperature applications like turbines, heat exchangers, burners, engine parts, or low-temperature applications like cryogenic environments. In addition to this, Inconel 718 has high resistance to oxidation and corrosion. It also offers excellent strength, with high yield, tensile, fatigue, and creep-rupture properties. The alloy is age-hardenable, has good machinability, and can be 3D printed, even into highly complex components.

Typical applications:

Components for demanding environments in the process industry

Burners and gas turbine components

High-temperature nozzles

Heat exchangers, valves, pumps, etc.

Main Characteristics:

Good tensile, fatigue, creep and rupture strength at temperatures up to 700 °C

Parts are easily precipitation hardened

Parts can be post-processed in both as-built and age-hardened states

Typical Part Properties

Delva uses metal powders that are designed and tested for use on EOS’ metal 3D printers. All EOS Inconel 718 powders have an inspection certificate (according to EN 10204, Type 3.1) showing the results of the extensive QA testing. Not only of the powder itself but also of test parts built on a dedicated system with a specific process.

3D printed Inconel 718

Delva uses AMS 5662 standard post-processing heat treatment for Inconel 718 to achieve the desired material properties. This material has good machinability and is easy to polish after the printing process, which allows the part to be finished with the desired surface.

Due to the difficulty of mechanical processing of Inconel 718, has the use of this material gained popularity and increased rapidly with metal additive manufacturing.

Inconel 718 is a high-strength, corrosion-resistant superalloy ideal for parts that will experience extreme temperatures and mechanical loading. The alloy’s combination of properties makes it usable for a wide range of demanding applications.

Delva recommends exploring the possibility of using Inconel 718 in current stainless-steel applications as the cost of metal 3d printing is mainly based on the actual printing time. Due to the strength of Inconel 718 can the component be designed substantially lighter, more sophisticated, and detailed, and therefore is the use of material massively decreased.

Delva uses metal powders that are designed and tested for use on EOS’ metal 3D printers. All EOS powders have an inspection certificate (according to EN 10204, Type 3.1) showing the results of the extensive QA testing of the powder itself and also test parts built on a dedicated system with a dedicated process.

At Delva, we use a validated process for printing that offers an optimal combination of parameters (e.g. laser power, layer thickness, etc.) to ensure that we consistently achieve the properties of the 3D printed parts.