Titanium Ti64 for Metal 3D Printing

+

When you need the best possible strength-to-lightness ratio for a component, titanium is the optimal choice.

Titanium Ti64

When you need the best possible strength-to-lightness ratio for a component, titanium is the optimal choice. Ti64 is a well-known light-alloy characterised by excellent mechanical properties and corrosion resistance, low thermal conductivity, combined with low specific weight and biocompatibility. This material is stronger than steel while weighing up to 40% less. Ti64 is a material with excellent mechanical properties for demanding applications.

As a 3D metal printed material, Ti64 is in the same cost range as traditional stainless steel, so it is worth considering it as a substitute already at the design table. With metal 3D printing, it is possible to produce highly cost-effective components of titanium that are both light and strong.

In addition to Ti64, also ask us about pure TiCP.

Typical applications:

Robotic grippers

Light machine parts

Competitive sports (motorsports, boats, etc.)

Medical components

Aviation components

Main Characteristics:

Excellent strength-to-lightness ratio

Excellent corrosion resistance

Good fatigue resistance

Typical Part Properties

Delva uses metal powders that are designed and tested for use on EOS’ metal 3D printers. All EOS powders have an inspection certificate (according to EN 10204, Type 3.1) showing the results of the extensive QA testing of the powder itself and also test parts built on a dedicated system with a dedicated process.

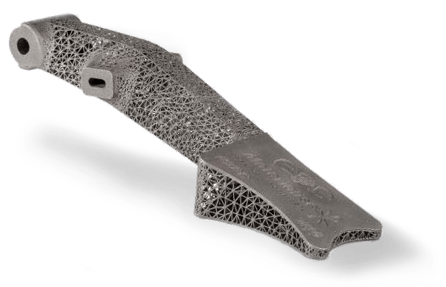

3D printed Titanium Ti64

Titanium has excellent material properties, but its high cost has historically limited its use. Additive manufacturing and optimised DfAM (Design for Additive Manufacturing) minimise the material usage and waste. The production time is also often decreased immensely compared to traditional methods. Titanium is becoming an industry favourite across a range of industry sectors as additive manufacturing enables cost-effective production.

Ti64 is emerging as one of the most interesting 3D printable metals due to its characteristics. It is very corrosion- and chemical resistant with a very high melting point. Titanium has a much higher tensile strength than most naturally occurring elements. These characteristics give titanium a distinct advantage in different demanding applications where you desire the best possible strength-to-lightness ratio for a component. With metal 3D printing, it is possible to produce highly cost-effective parts of titanium that are both light and strong.

3D printed titanium has some apparent benefits to offer for many applications. 3D printing titanium into shapes that are impossible with traditional manufacturing and fabrication methods offers industrial designers a whole new set of design rules that are considerably less restrictive. Metal 3D technology also enables fast prototyping and manufacturing of series at a much lower cost.

Metal additive manufacturing has rapidly become recognised as a mature manufacturing method. This development accelerates the availability of titanium to various industries.

At Delva, we use a validated process for printing that offers an optimal combination of parameters (e.g. laser power, layer thickness, etc.) to ensure that we consistently achieve the properties of the 3D printed parts.