Stainless Steel 316L for Metal 3D Printing

+

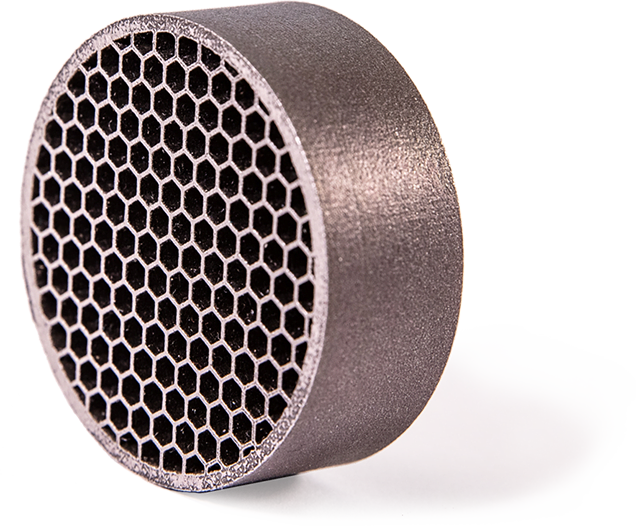

Stainless Steel 316L is a standard material for numerous applications, and the printed components show a high level of corrosion resistance and ductility.

Stainless Steel 316L

Components made of Stainless Steel 316L have high tensile strength, temperature, and corrosion resistance. In addition, they are with high ductility and wear resistance and can be easily machined and polished. Due to the low carbon content of the mixture, the material has good weldability, and it is easy to attach the printed parts to traditionally made structures by welding. 3D printed Stainless Steel 316L parts are compact and have at least the same properties as machined 316L material. They are fully dense parts having excellent toughness and suitable for industrial applications.

Typical applications:

Food industry

Chemical industry

Heat exchangers

Enclosures

Consumer products

Main Characteristics:

High ductility and toughness

High strength

High corrosion resistance

Typical Part Properties

Delva uses metal powders that are designed and tested for use on EOS’ metal 3D printers. All EOS powders have an inspection certificate (according to EN 10204, Type 3.1) showing the results of the extensive QA testing of the powder itself and also test parts built on a dedicated system with a dedicated process.

3D printed Stainless Steel 316L

At Delva, we use EOS Stainless Steel 316L that is a high-performance marine-grade austenitic stainless steel. The material is molybdenum alloyed for enhanced corrosion resistance in chloride environments.

Components 3D printed from 316L are durable and have excellent toughness. The elongation is also good. 3D-printed 316L is suitable for applications where a non-corrosive material is needed, for example, materials applicable for the food industry. Stainless Steel 316L is a standard material for numerous applications. 316L printed components show a high level of corrosion resistance and ductility. In addition, this material has a high resistance to acids. This combination is ideal for a wide range of applications in process, energy, food, transportation, automation, shipbuilding, and many more. Stainless Steel 316L is often used in the process and paper industries, but the use extends even further to more demanding applications, as the aerospace and oil and gas industry.

At Delva, we use a validated process for printing that offers an optimal combination of parameters (e.g. laser power, layer thickness, etc.) to ensure that we consistently achieve the properties of the 3D printed parts.