Tool Steel MS1 for Metal 3D Printing

+

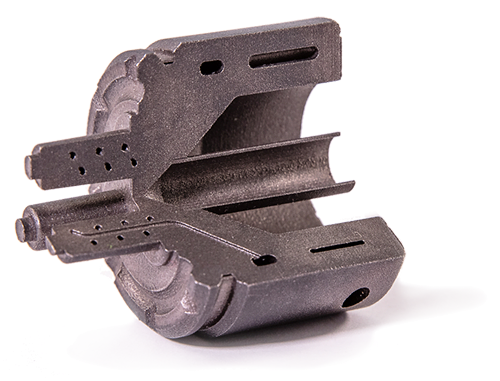

Tool Steel MS1 is a hard tool steel with a strength of approximately 2000 MPa. It is suitable for tool production and end-use components that require particular strength.

Tool Steel MS1

Tool Steel MS1 is characterized by having excellent strength combined with high toughness. The material has excellent mechanical properties and is easily heat-treatable using a simple thermal age-hardening process to obtain excellent hardness and strength. The material achieves a hardness of approximately 55 HRC by heat treatment. This material is ideal for many tooling applications such as tools for injection moulding, die casting of light metal alloys, punching, and extrusion. Even when hardened, has MS1 steel high machinability and the material can be polished up to class B1.

Typical applications:

Injection moulds

Tools and equipment

Structural components requiring high strength

Components that require durability

Main Characteristics:

Very high strength and hardness

Properties adjustable with different heat treatment

Good machinability

Typical Part Properties

Delva uses metal powders that are designed and tested for use on EOS’ metal 3D printers. All EOS titanium powders have an inspection certificate (according to EN 10204, Type 3.1) showing the results of the extensive QA testing. Not only of the powder itself but also of test parts built on a dedicated system with a specific process.

3D printed Tool Steel MS1

Tool Steel MS1 is a hard tool steel with a strength of approximately 2000 MPa. It is suitable for tool production and end-use components that require particular strength. MS1 steel cannot be considered stainless steel, but nickel, cobalt, and molybdenum used as alloys help resist corrosion.

MS1 is a hardenable steel with excellent machinability for many tooling applications. In both as-built and age-hardened states, the components can be machined, spark-eroded, welded, micro shot-peened, polished, and coated if required. With a hardness of around 55 HRC, it is particularly suitable for mold inserts, tooling production, and other end-use components requiring superior strength. Also, for high-performance industrial and engineering parts, for example, in aerospace and motor racing applications tool steel MS1 is very suitable.

Components built in EOS Tool Steel MS1 have a chemical composition corresponding to US classification 18% Ni Maraging 300, European 1.2709, and German X3NiCoMoTi 18-9-5. This Tools Steels composition is characterised by having excellent mechanical properties and being easily heat-treatable using a simple thermal age-hardening process to obtain superior hardness and strength.

Tool Steel MS1 is a cost-effective material for prototype projects where you want to study the shape of a component before the actual production.

At Delva, we use a validated process for printing that offers an optimal combination of parameters (e.g. laser power, layer thickness, etc.) to ensure that we consistently achieve the properties of the 3D printed parts.