In metal printing, the powder bed fusion method recycles the material throughout the printing process. With high-quality equipment, this is done safely and without compromising printing quality.

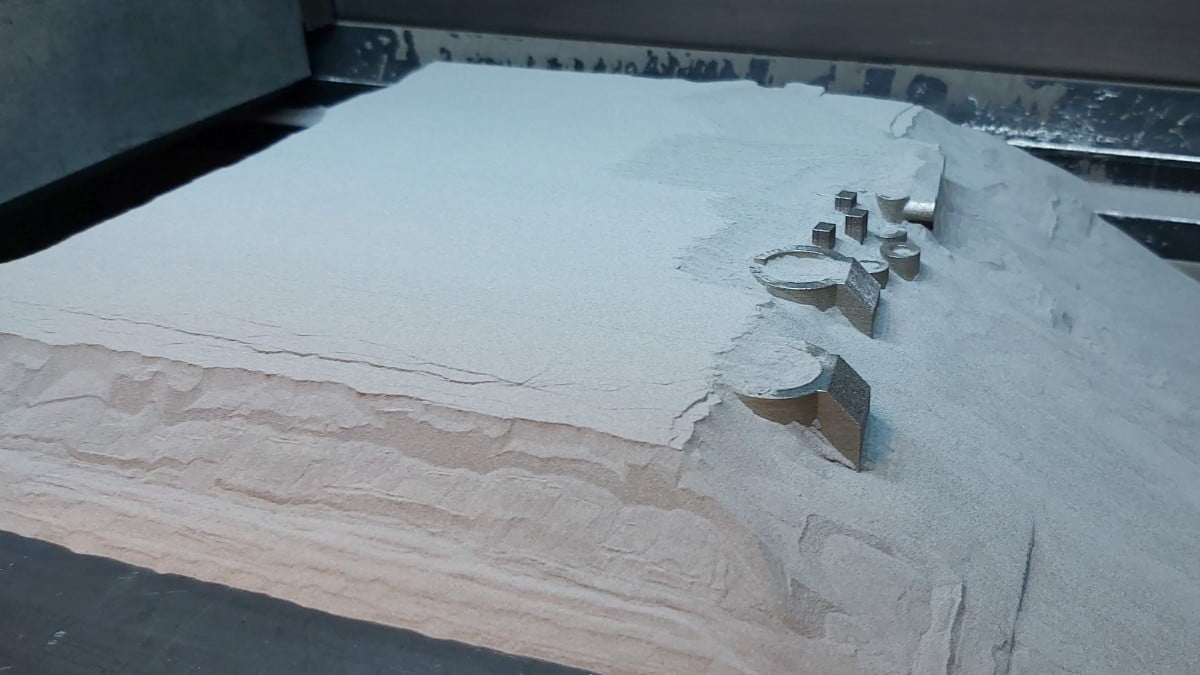

In the additive manufacturing of metals by powder bed fusion, is powder recycling an essential part of the process. When printing components, the powder is spread to the entire printing plate. The desired parts are melted from the powder by laser layer by layer. The height of the components determines the volume of powder required in the process. In printing, much of the applied powder remains unused and is finally vacuumed around the pieces for recycling.

Recycling makes sense

From time to time, the use of virgin powder in printing becomes a requirement, and the mixing of powder batches is causing concerns. The use of virgin powder alone in printing is possible but does not make sense for the component. The material loss is then very high, and the price of the component increases too. More important is to monitor the use of powder batches and mixing ratios.

When the powder is melted layer by layer, its properties change slightly around the piece each time it is recycled. The powder particles melt together into a larger one and some of the finest powder disappears with the flow of shielding gas to the filters. Larger particles cannot enter from the sieve into the process, but the absence of small particles impairs the spreadability of the powder in the long run. For this reason, the powder must be renewed at certain intervals by mixing it with new powder.

There are differences in materials

Materials behave differently. The most difficult to recycle are reactive materials such as titanium and its alloys. These react with oxygen during the handling of the material as well as during the process, which affects the properties of the part. However, in tests of titanium used in medical applications, it has been found that although the oxygen as well as the nitrogen content in the powder increase, they are still within the limits of the fresh powder even after 30-35 uses.

When recycling materials, it is advisable to monitor the static strength values to ensure quality, and it is easy to print the drawbars from time to time alongside other parts. Existing research data is also available and it can be seen that the normal recycling of the powder does not significantly affect the strength properties, be it aluminum, titanium, nickel alloys, or steel. Ti6Al4V material has even been shown to improve its mechanical properties during the first few recycling cycles. Thus, the printed parts can be used without any concerns according to the material values given by the equipment manufacturers.

Critical items

Critical items, such as those related to personal safety, may end up requiring that all items are always made from unused powder and the same batch of powder. The aim is to achieve the same technical values. However, we consider this is not necessary. The monitoring of the powder becomes important. The manufacturer must be able to calculate the number of uses per batch and the age at which the powder is used. An accurate record must be kept of recycling. Even Airbus, which operates in such a demanding sector as the aircraft industry, accepts e.g. the computational method for the proportions of the different alloying elements. Random tests for strengths are, of course, performed, but by calculating the mixing ratios it is possible to ensure that the powders remain within the promised limits for certain properties.

For further information:

Markku Lindqvist, CTO, markku.lindqvist@delva.fi