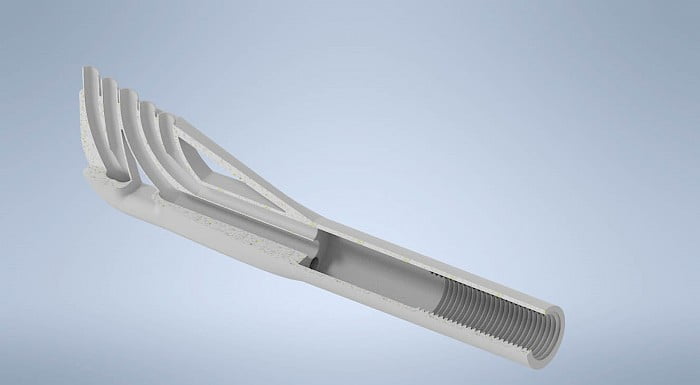

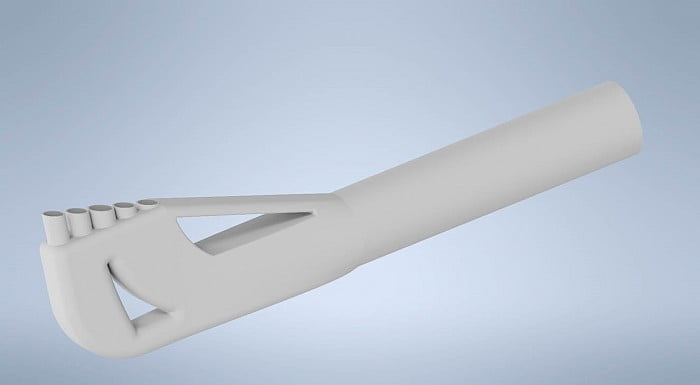

The freedom of shape provided by Additive Manufacturing makes it possible to improve the efficiency of nozzle structures. There is no need to design the nozzle from the manufacturing point of view anymore. AM enables maximum freedom of design and the nozzle can be designed with the best flow characteristics in mind.

For example, can the channel structure be manufactured with AM to allow the part to be more efficiently cooled from the inside. The materials passed through the nozzle can be designed to mix more efficiently and the mixture can also be directed in a precise direction. You can also lighten the weight of the parts significantly with the right material choices and optimized structures will minimize the space needed.

3D printed nozzle, rendered image ©Delva.

Metal printing offers a new approach

Printing significantly reduces the need for assembly when you manufacture only one component instead of machining dozens and assemble multiple parts together. This saves time, money, and working hours as well as the need for logistics in the supply chain.

A wide range of materials allows for a variety of applications. For example, nickel alloys are suitable for conditions hotter or more corrosive than many other materials and thus reduce the need for cooling.

With the freedom of shape, a wide range of functionality can be agilely designed for printable nozzle pieces. This does not test 3D printing of metals as a manufacturing technology, but our ability to create new solutions. Your R&D can genuinely benefit from the possibility of producing a printing plate full of parts, each of them slightly differing from another. Running tests with these extensive series of variants allows a company to come up with the most optimal solution in an agile way, cost-efficiently with long-term benefits.

3D-printing widely used in industrial applications

Delva’s customers have successfully been able to vastly increase efficiency and durability of the nozzles designed for and manufactured with industrial metal AM.

Some food for thought with these rendered images that demonstrates possibilities enabled by AM.

For additional reading have a look at this example from GE Aviation: Fuel efficiency up to 15 percent better.