Supply chains and security of supply have been a hot topic this spring. Availability problems have highlighted the risks posed by long supply chains.

Shortages have appeared in both standard and special parts. When the production process stops due to a lack of spare parts, the losses can be outstanding. Still, it is worth considering whether spare parts inventories will be significantly increased in the future to avoid problems. Inventories increase committed space, capital, and potential waste. Alternatively, a wider range of means can be considered. Of course, the challenge is not limited to end-users of machinery and equipment, but also manufacturers, who are bound by the readiness to supply spare parts for a long time. The manufacture of individual spare parts is also known to be expensive due to, for example, model and tool costs.

There is a growing interest in digital spare parts. They are spare parts for which related information is transferred and stored digitally. They are made, for example, by 3D printing, typically close to the user. In addition to the challenges outlined above, local manufacturing will also eliminate transport needs. A study carried out by VTT, Aalto, and several partner companies in 2016-2017 found that at least about 5% of companies’ spare part needs are suitable as digital spare parts.

In addition to the digitally stored spare parts described above, an interesting opportunity is to improve the availability of slow-moving spare parts for old equipment and machines by 3D printing. Printing speeds up, print sizes increase, and costs don’t usually become a barrier when looking at the whole. The slowdown in these cases is that 3D models are typically missing and must first be created to allow printing. 3D scanning and printing together can solve major spare parts challenges. Read our website for a much-talked-about example.

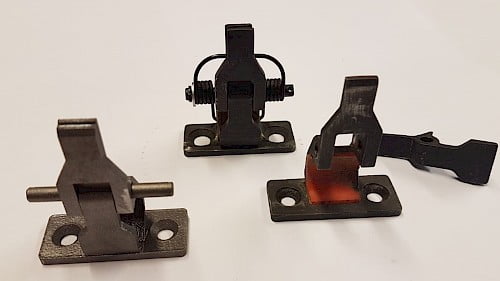

3D scanning is not always necessary. In our photo example, the part to be replaced was measured at our office by hand. The modeled parts were assembled on a computer screen. The observed inaccuracies could be corrected and the 3D models were ready to print. Printing proved to be the most cost-effective way to solve the need for spare parts in terms of time and cost.

Contact info@delva.fi or via the contact form on our website.